Unbreakable Bonds: The Power Behind Gorilla Grip

Key takeaways

-

Gorilla Grip is a high-strength construction adhesive trusted by Kiwi tradies for decades.

-

Delivers strong initial grab and long-lasting bonds on common porous building surfaces.

-

Suits interior and exterior work, with moisture resistance for site conditions.

-

Pair with SMX products where flexible, paintable bonding is required.

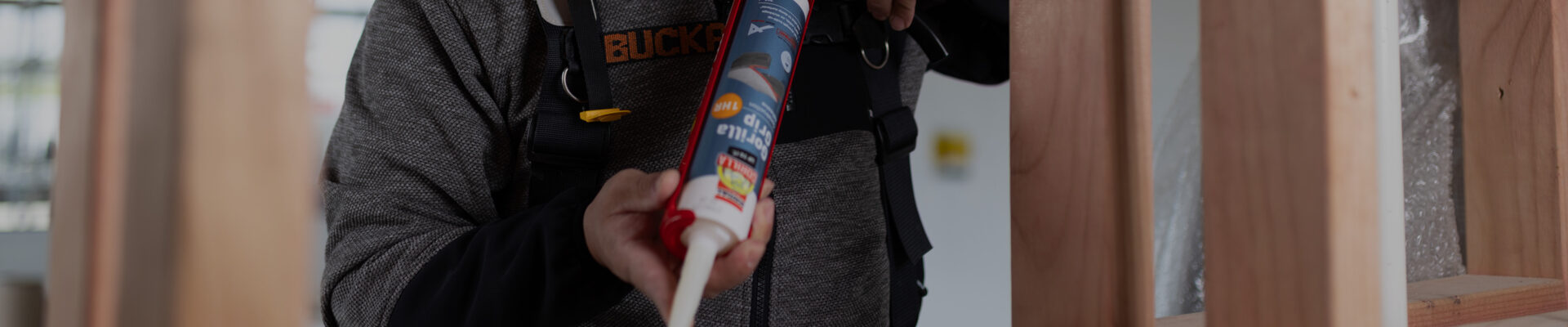

When strength matters, there’s one product that dominates all other construction adhesives in New Zealand – Gorilla Grip.

Manufactured globally by Soudal, Kiwis use more Gorilla Grip per head of population than anywhere else in the world. And there’s good reason why local builders have relied on the Gorilla brand for 30 years.

Strength. Reliability. Versatility.

Why Gorilla Grip Outperforms Traditional Construction Adhesives

Gorilla Grip adhesive easily out-performs solvent-based adhesives and creates permanent connections between porous materials that are impossible to break. It will absorb nearly 6000 newtons of pressure – 40% more than solvent-based construction adhesives. Extensive destruction testing proves your substrate will most likely break before your joint does.

Built for Wet Conditions: Moisture-Resistant and Reliable

Because Gorilla Grip is a polyurethane-based construction adhesive, it can cope with a high moisture content. It expands as it cures, drawing moisture from the substrate or atmosphere and pushing into the cellulose timber fibres to grip them tight. By contrast, a solvent-based adhesive only sticks to the surface and won’t bond properly if the timber’s moisture content is above 18%. Rainy days, dewy mornings, and products exposed to the elements all pose a risk of adhesive failure. If you end up with squeaky floorboards, solvent-based adhesives are the number one cause.

Where You Can Use Gorilla Grip

This powerful product can be used to assemble joists, erect framing, attach timber panels to frames, fix flooring panels, lay decks, install plywood roofing panels, attach timber plates to concrete pads, and assemble wooden and kitchen joinery.

Recommended by NZ’s Leading Flooring Brands

Gorilla Grip’s proven reliability is why Kopine Flooring specifies its use to maintain the warranty on its flooring panels. Laminex Strandfloor and Ecoply Flooring also recommend Gorilla Grip. Using the same product to join the edges of flooring panels together, and attach them to joists, makes life simple and guarantees you won’t have to deal with complex and time-consuming squeaky floorboard repairs down the track. Flooring materials must be clamped or mechanically fastened during the curing process, allowing you to achieve a perfect high-end finish.

Low VOC and Waterproof: Perfect for Healthy Home Builds

The product is low VOC to meet healthy home standards and as a D4 rated adhesive, it offers the highest level of moisture resistance so correctly constructed joints are waterproof.

Choose the Right Gorilla Grip for the Job

Gorilla Grip comes in three options – 10 minutes, 1 hour and 2 hour. In all cases, final end strength is achieved in 24 hours once fully cured. Our 10 minute cartridge (300ml) is ideal for small, quick jobs as you’ll have five minutes working time. Your materials only need to be clamped in place for 10 minutes before you’re good to go.

Easy to Use with a Professional Finish

Our 1 hour cartridge (300ml) is BRANZ appraised and has a 15 minute working time (clamps can be removed after 1 hour). While our 2 hour product comes in both a cartridge (300ml) and a sausage (600ml). The latter is an economical option and will give you 30 minutes of working time, allowing you to reposition materials as you go. The sausage option will reduce your amount of waste to landfill, and is also BRANZ appraised.

Easy to Use with a Professional Finish

In all cases, Gorilla Grip is easy to gun on and is the consistency of a thick gel. It will stay put and won’t slump, so works equally as well on vertical or horizontal surfaces.

Pro Tips for Using Gorilla Grip

To get the most out of Gorilla Grip, here’s some handy tips: your two surfaces must be closely fitted (touching); if the weather is hot and dry, wipe your timber surface with a damp cloth first to provide some moisture for curing; and if you need to wipe up or remove some product, let it cure first before peeling or trimming it off with a sharp knife.

Trusted by Kiwi Builders for 30 Years

New Zealand builders rely on Gorilla Grip for its brute strength, knowing it will hold tight on whatever porous surface they apply it to. But beyond its sheer muscle, Gorilla Grip offers a range of benefits that make it an essential tool for any building project.

Contact Soudal for trade advice, or find a stockist near you.

Gorilla Grip FAQs

Yes for exterior use once the surface is clean, sound and free from standing water. Lightly damp timber is usually fine. Avoid saturated substrates. For wet or flexible joints, consider an SMX hybrid adhesive.

You can paint adjacent surfaces, but most construction adhesives are not designed as a paintable finish. If a paintable bond line is required, use a paintable SMX adhesive or a compatible sealant.

Avoid polyethylene, polypropylene, PTFE and very oily or bituminous surfaces. Test first on powder-coated metals and delicate laminates. For PVC or mirrors, use a product rated for those materials.

Initial grab forms in minutes. Light handling is typically possible after 30 to 60 minutes, with full strength after 24 to 48 hours depending on temperature, humidity and joint thickness.

For overhead loads, safety-critical applications, or where movement is expected, use temporary or permanent mechanical fixings in addition to the adhesive.