Why Adhesives Fail

The following information explains how and why adhesive products fail and how to recognize the difference between the three different types of failures.

There are three types of failure:

1. Cohesive Failure

2. Adhesive Failure

3. Substrate Failure

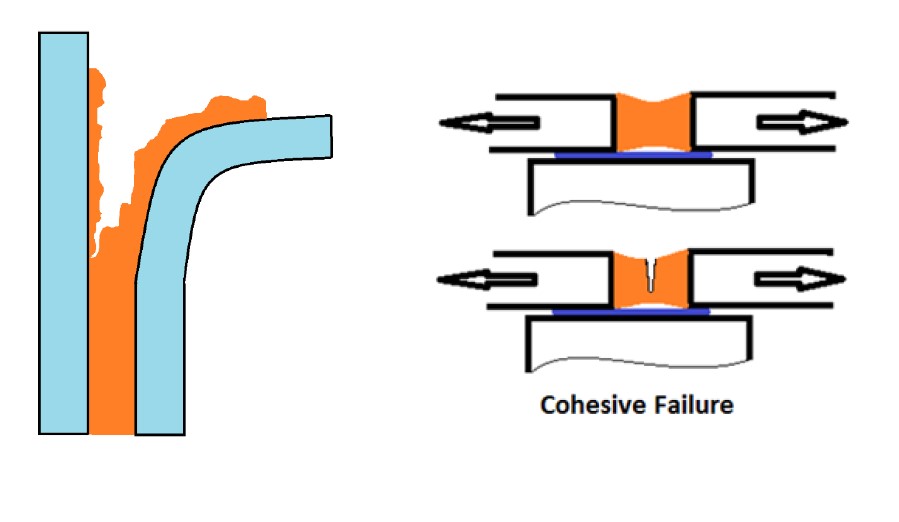

1. Cohesive Failure and Fracture

This is where the adhesive breaks away within itself (breaks the cohesive bond). It is generally considered when testing an adhesive that any failure where greater than 5% of the adhesive separates from itself is a fail.

This type of failure is more desirable than adhesive (example 2) failure as it demonstrates that the bond to the substrate is greater than the internal cured structure of the adhesive.

Possible causes of Cohesive failure:

• When curing the movement characteristics of the substrates is greater than the joint design.

• Defects in the adhesive curing process (including unwanted movement during curing)

• Defects within the applied adhesive eg. bubbles, pores etc

• Ageing in the adhesive bonding over time

What is looks like:

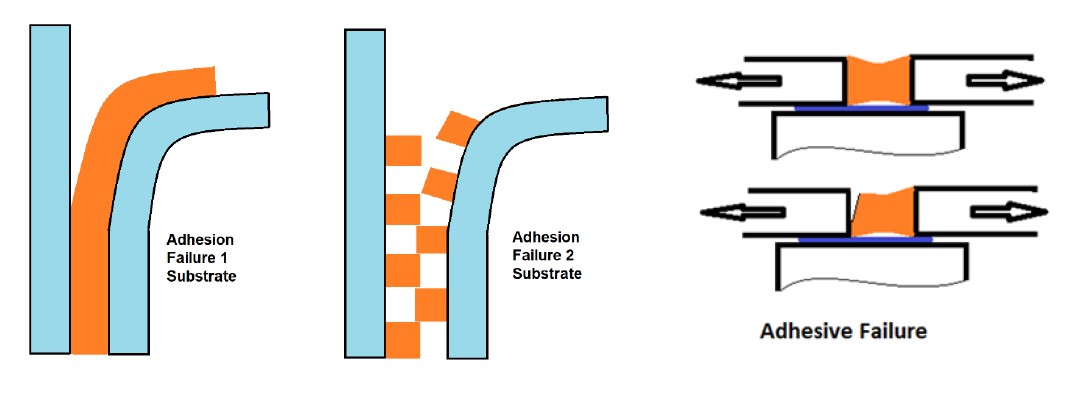

2. Adhesive Failure

This is where the adhesive breaks away from the substrate it has been applied to. It is generally considered when testing an adhesive that any failure greater than 5% adhesive separating from the substrate is a test failure.

In this type of failure, the adhesive is totally or partially separated from the substrate surface. The adhesion fracture can occur across either one or on both substrates. Adhesive failure demonstrates that the bond to the substrate is less than the internal cured structure of the adhesive.

Possible origins and causes:

• The preparation of the substrate surface preparation before application of the adhesive was incorrect or incomplete

• Improper use of primers or activators required by the adhesive, inadequate evaporation time, inadequate thickness etc

• Using the adhesive past its “Best Before” date, preventing the wetting of the adhesive on the substrate

• The selection of the adhesive to match the substrate is wrong

• There has been ageing phenomena between the substrate and the adhesive

What is looks like:

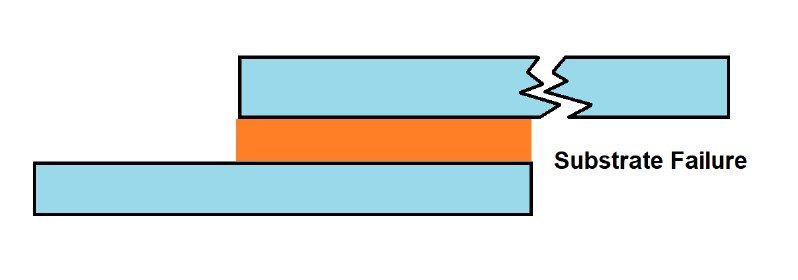

Substrate Failure/Fracture

This is exactly what it sounds like, the substrate is weaker than the applied adhesive. So you see a break within the internal structure of the substrate.

Possible origins and causes:

• The substrate is not sized or calculated to withstand the load that has been exposed

• Physical or chemical attack (age, acid solutions, alkaline, corrosion etc) to the substrate resulting in deterioration in their mechanical properties

• The resistance of the substrate is less than the adhesive bond strength

What is looks like:

Want to save this guide? Download the PDF version here